As a result of their combination of security, simplicity, and convenience, slam latches have acquired popularity among securing mechanisms. These sturdy fastening mechanisms are dependable for securing doors, panels, cabinets, and other enclosures in various applications. In industries such as automotive, aerospace, marine, and industrial apparatus, where rapid access and secure closure are essential, slam latches are favored. This article examines the impact of latches’ functionality, advantages, and diverse applications, emphasizing their key features and benefits in various settings.

Performance of Slam Latches

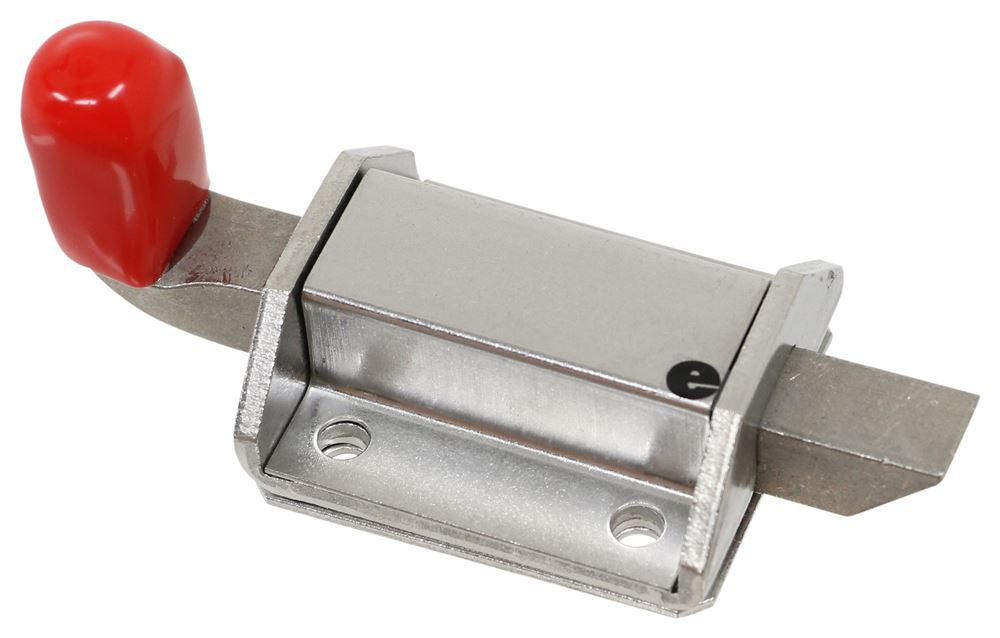

Slam fasteners are a straightforward and efficient method for securing doors and panels. In contrast to conventional latches requiring manual operation, slam latches permit rapid and uncomplicated closure. These latches are designed to seal automatically when a door or panel is struck, hence the name “slam latch.” The force of the closing motion activates a mechanism within the clasp, securing the closure without additional actions or hardware.

The striker plate is the primary component of an impact fastener, which is typically affixed to the secured door or panel. This plate has a curved or angled surface that, when closed firmly, aligns with the locking mechanism. When a door or panel is rammed shut, the striker plate engages and locks the fastener by making contact with it. This mechanism offers a robust and dependable securing solution, even in harsh environments.

Advantages of Slam Latches

Several main advantages of slam closures make them the preferred choice in various industries. Their simplicity of use is a significant advantage. The latch automatically secures the enclosure with a simple impact on the door or panel, eradicating the need for manual operation or additional hardware. This feature significantly increases productivity and saves valuable time, making slam closures ideal for applications where fast access is crucial.

Durability and dependability are additional advantages of impact closures. These fastening devices, made from high-quality materials such as stainless steel or reinforced polymers, can withstand severe conditions and extensive use. They are corrosion-, impact-, and vibration-resistant, assuring durability in demanding environments.

Uses for Slam Latches

The adaptability of impact closures enables their use in various industries and applications. Here are some instances:

- Automotive: Automotive applications, including doors, hoods, trunks, and passenger compartments, frequently employ slam fasteners. Their fast and secure closure protects the vehicle’s contents and ensures occupant safety.

- Aerospace:The aerospace industry utilizes Slam fasteners on aircraft doors, access panels, and stowage compartments. Their dependable securing mechanism facilitates efficient access and strengthens the security of vital compartments.

- Marine: In the marine industry, slam fasteners are commonly used to secure hatches, cabinets, and stowage compartments on vessels and ships. The robust construction of slam closures enables them to withstand exposure to salinity and harsh marine conditions.

- Industrial Machinery and Equipment:Slam fasteners are essential for securing industrial machinery and equipment enclosures. They are commonly found in control panels, electrical cabinets, and machinery access doors, providing rapid and dependable closure for the safety of operators and the preservation of apparatus.

Conclusion

Slam fasteners have proved to be effective for securing doors, panels, and enclosures in various settings. Their automatic securing mechanism, user-friendliness, sturdiness, and enhanced security make them an industry-wide favorite, including in the automotive, aerospace, marine, and industrial equipment sectors. By providing fast access with a simple thud and eliminating the need for additional manual operation or hardware, slam closures save time and increase productivity.